Author: Jinwook (James) Chang

Mentor: Dr. Anthony Dichiara

Shanghai American School Puxi Campus

Abstract

As global demand for sustainable energy solutions grows, nanogenerators have emerged as a promising technology for the ability to convert various forms of energy into electricity at small scales. This review focuses on two particularly unexplored but rapidly advancing subfields: Moisture-sorption-based Energy Harvesting (MSEH) and Transpiration-driven Electrokinetic Power Generation (TEPG). Both technologies convert moisture and water flow into usable electricity without the need for external power sources. MSEH leverages the ion migration resulting from water molecule sorption and desorption on hygroscopic sorbents, while TEPG generates electricity through transpiration-like capillary-driven flow and electrokinetic interactions within charged nanochannels. Through an in-depth analysis of recent eight most highly cited publications in TEPG, this paper examines the impact of sorbent composition, form factor, and water environments on device performance. Researches yielded high results when sorbent were cotton-based systems, particularly those enhanced with conductive additives like Carbon Black and MXene, and in ionized water environments. Furthermore, the recent trends in the number of MSEH and TEPG publications simulates the early-growth trajectories of triboelectric and piezoelectric nanogenerators, highlighting their rapid growth and significant potential. Although the current power outputs are insufficient for commercial electronics, continued advancements in sorbent material and hybrid integration promise a strong future.

Keywords: moisture-induced energy harvesting (MSEH), transpiration-driven electrokinetic power generation (TEPG), nanogenerators, energy harvesting, sorbent material.

1. Introduction

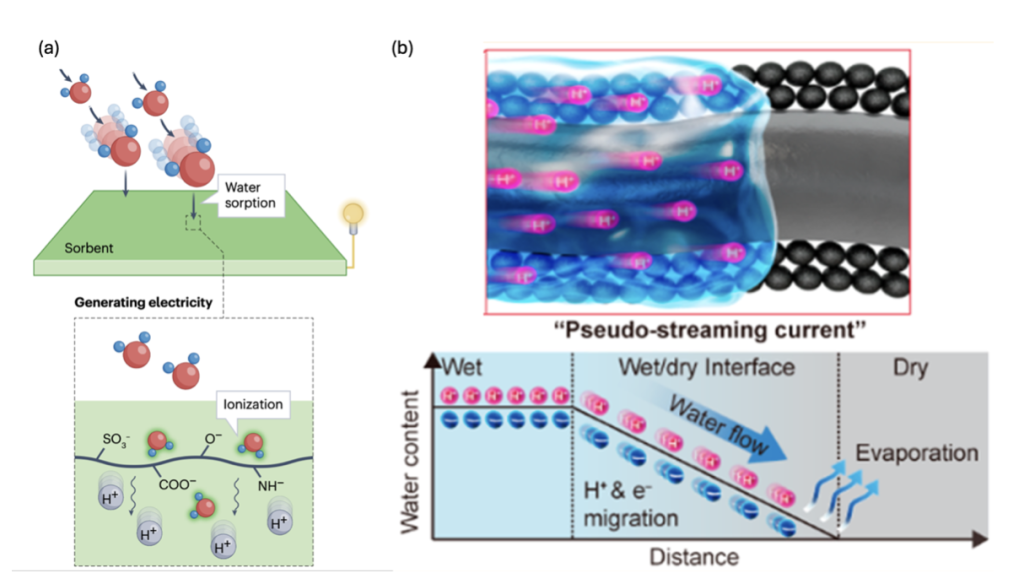

As the global demand for sustainable energy solutions grow, harvesting energy from ambient environments, such as heat, light, and humidity, has opened a vital research frontier. Among these, Moisture-Sorption-Based Energy Harvesting (MSEH) offers a unique advantage: continuous operation under low-resource conditions. Through MSEH, energy can be generated through just a solvent and moisture: when water vapor sticks to a sorbent, it forms bonds and releases heat; when water evaporates off a sorbent, it absorbs heat from surroundings, which produces a cooling effect. During this process, constantly adsorbed and desorbed, water molecules interact with hydrophilic groups on sorbents, leading to ion migration, which generates voltage and current. More specifically, water molecules in the atmosphere interact with the hydrophilic parts of the sorbent. This interaction causes ions to dissociate and move from the surface inward. This movement of charges creates voltage and current—thus generating electricity. Figure 1 illustrates this process, demonstrating how moisture uptake and evaporation drive charge movement within a hygroscopic material.

Likewise, Transpiration Electrokinetic Power Generation (TEPG), employs passive water gradients to generate electricity through nano/microscale interactions. However, the key difference between MSEH and TEPG lie on its source of water uptake. Whereas MSEH absorbs atmospheric moisture, TEPG implements a capillary action to absorb water through a porous, hydrophilic sorbent—just like in plant stems in transpiration. As water evaporates, a continuous water flow remains as the sorbent pulls more water upward, and electrical double layer forms at the carbon/water interface, gathering protons on the wetside. Then, water flows through charged nanochannels and drags along ions, creating potential difference and electric field as a result. Through placing electrodes on two ends of the channel, the process produces usable electricity. Figure (b) illustrates the principle of TEPG, indicating how capillary-driven water flow and ion transport across nanostructures lead to voltage generation in carbon-coated cotton fabric.

As electricity and power generation for both MSEH and TEPG processes are highly dependent on the sorbent’s ability to attract more water, sorbent selection and optimization possess vital influence on the efficiency of these two processes. Notably, Yun et al. (2019) implements a cellulose membrane for its highly hydrophilic porous abilities, while Kaur et al. (2021) utilizes microporous alumina ceramic. Out of the ten most highly cited articles on MSEH, seven researches indicated uses of hygroscopic cellulose structures, while three researches indicated uses of applied hydrogels, such as the nylon and hydrogel-based composite fiber in Chen et al. (2023). For all sorbents in the top ten highly cited articles in Moisture-Sorption-Based Energy Harvesting, hydrophilicity and porosity stood out as the two main determinants of energy generation performance. Further, an innovative study has been conducted in Bae et al. (2022), as they combine MXene (Ti3C2Tx) with cellulose, applying MXene’s metallic-like electrical conductivity for enhanced charge transport, while enhancing sorbent hydrophilicity, as surface functional groups, including -OH, -O, and -F, attach to MXene. The following review conducts a detailed analysis on notable trends in the MSEH and TEPG renewable energy and researches the effects of different sorbents on power generation, analyzing sorbent selection in the top ten highly cited articles in the field.

II. Market Growth and Applications of Nanogenerators

Despite its “infancy” status in 2015, the nanogenerat market has since grown exponentially. As of 2022, the nanogenerator market is already valued at USD 39.5 Billion, and it is forecasted to reach USD 67.44 Billion by 2030, growing at a CAGR of 8.2% (Virtue Market Research, 2025). Others report the nanogenerator market to grow at a CAGR of 18.8% by 2033 (Verified Market Reports, 2025). More specifically, one forecast estimates the triboelectric nanogenerators (TENGs) market, a section of the nanogenerator market, growth from USD 1.47 Billion in 2023 to about USD 13.56 Billion by 2033, a staggering ~24.88% CAGR over that period (Spherical Insights, 2024). This rapid acceleration reflects not only early-stage promise but also a clear shift toward mainstream adoption across sectors. With applications expanding across healthcare, agriculture, smart infrastructure, and consumer electronics, nanogenerators are gaining traction as key power generation sources of self-powered devices (Market Growth Reports, 2025).

Despite its mere certification in the lab environment, this technology holds vast potential as a low cost, low maintenance energy harvesting method, especially as sustainability and energy efficiency become global priorities. One of MSEH and TEPG’s notable applications include power generation for various sensors and detectors. In example, MSEH can be applied to power air quality monitors, while TEPG may be implemented to soil or plant monitoring systems in precision agriculture. Moreover, MSEH can be applied in wearable electronics to power low-energy health trackers or e-textiles and in smart packaging to maximize freshness of fruit/vegetable deliveries. On the other hand, TEPG can be embed in walls or roofs to harvest energy from water flow and temperature gradients. These technologies can further combine with other popular renewable energy technologies in the market, achieving higher sustainability. For example, a layer of transparent MSEH sorbent may be applied as a final layer on top of photovoltaics, enabling battery-free solar cells to be powered all through night. Although there are various factors still to be considered, both technologies hold significant potential in the future renewable energy generation.

Moreover, nanogeneration plays a vital role in diversifying energy sources. Suburban America suffers from blackout after blackout—Texas alone saw 264 major outages since 2000—costing over USD 15,000 to 90,000 in less than 30 minutes (Statista, 2017). However, nanogenerators may help resolve this issue. Since most nanogenerators, including triboelectric, piezoelectric, thermoelectric, moisture-induced, and transpiration-electrokinetic, do not require a major applied external force to generate electricity, they can minimize the losses from power outages by consistently circulating electricity through the system, until major electricity sources begin to supply as normal.

III. Research Trends in Nanogenerators

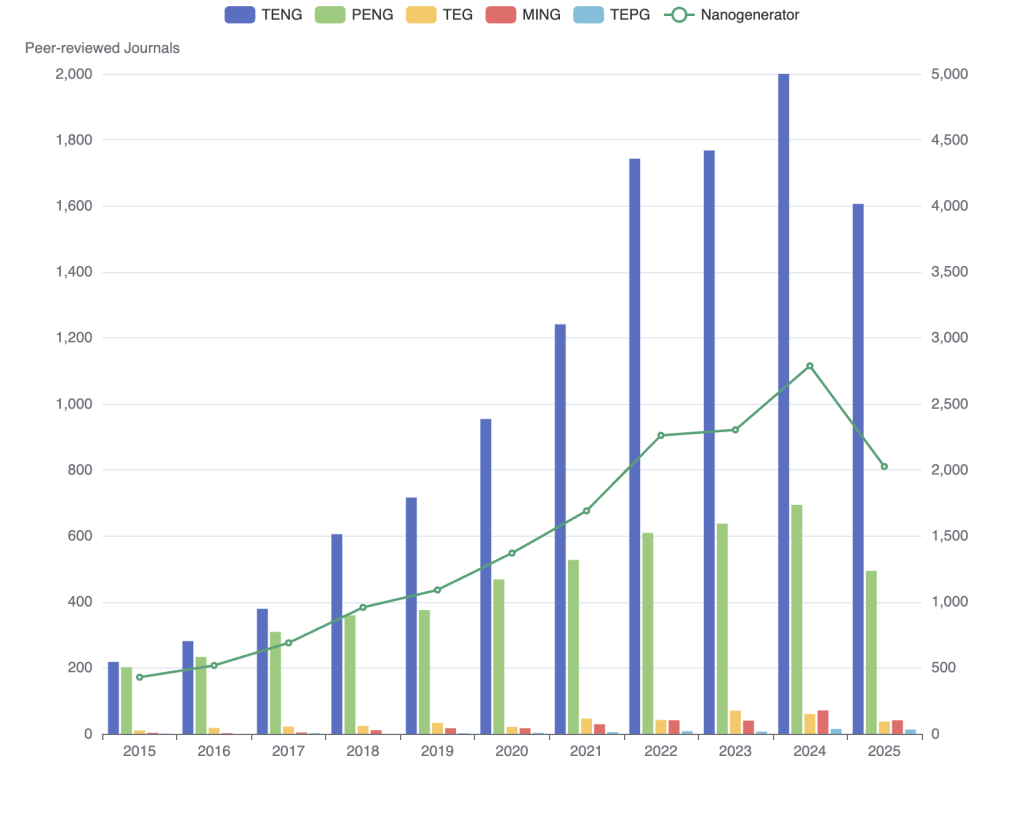

In Figure 3, six keywords have been researched, including triboelectric (TENG), piezoelectric (PENG), thermoelectric (TEG), moisture-induced (MING), transpiration-driven (TEPG), and nanogenerators, using the Web of Science database accessed through the University of Washington online library. The primary y-axis exhibits the number of peer-reviewed articles for each nanogenerator subcategory, while the secondary y-axis indicates the number of peer-reviewed articles related to nanogenerators as a whole. Among the various nanogenerators explored over the past decade, 90% of them involves mechanical energy conversion—TENG (67.5%) and PENG (28.4%)—while other technologies rely on thermal or chemical energy conversions—TEG (2.2%), MING (1.6%), and TEPG (0.3%).

As shown in Figure 3, the number of peer-reviewed articles on nanogenerators has been rapidly increasing over the past decade, with an approximate increase of 549.65% between 2015 and 2024—a near sixfold increase in under a decade. This growth far exceeds increasing rates in broader “energy harvesting” publications, which also grew substantially—from 3,858, in 2015 to 9,226 in 2024. Most notable increases happened in mechanical energy subcategories, including the triboelectric nanogenerators, more than tenfolding from 218 in 2015 to 2,788 in 2024, and piezoelectric nanogeneratores, tripling from 202 in 2015 to 694 in 2024. The sharp increase in the number of publications not only indicate rapidly growing academic curiosity and attention on nanogenerators but also validates the technical feasibility of nanogenerators.

Although not as significant as triboelectric and piezoelectric nanogenerators, more niche branches, such as the moisture-induced nanogenerators and transpiration-driven electrokinetic power generators have attracted attention to increasing number of researchers, as shown from the data above: moisture-induced increased from 3 in 2015 to 71 in 2024, while transpiration-driven increased from 1 in 2015 to 15 in 2024. Nevertheless, since water harnessing-induced energy generation is in the early stage as demonstrated by the figures above, it follows the early growth trajectories of TENG and PENG, as most research on these subfields have been conducted in the recent five years. This highlights a potential rocketing interest in the following couple of years. In fact, upon further data analysis, as shown in Figure 4, all keywords, even including “energy harvesting,” recorded the maximum R^2 value when data points were put into quartic equations. This quartic regression implies a steep increase over the past decade and a continuously increasing trajectory in near future.

Table 1. Correlation coefficient values of the number of publications related to nanogenerators as a function

| Energy Harvesting | Nano- generators | TENG | PENG | TEG | MING | TEPG | |

| Linear | 0.9885 | 0.9667 | 0.9571 | 0.9903 | 0.8297 | 0.8655 | 0.7547 |

| Quadratic | 0.9886 | 0.9889 | 0.9863 | 0.9911 | 0.8545 | 0.9548 | 0.918 |

| Cubic | 0.9888 | 0.9898 | 0.9886 | 0.9926 | 0.8551 | 0.9608 | 0.9255 |

| Quartic | 0.993 | 0.99 | 0.9891 | 0.9934 | 0.8898 | 0.9702 | 0.934 |

| Exponential | 0.9753 | 0.9855 | 0.9811 | 0.9736 | 0.8615 | 0.9341 | Error |

Since Moisture-Sorption-based Energy Harvesting (MSEH) and TEPG operate in low-light, low-thermal, and off-grid humid environments, its versatility projects a rapid growth in the following decade. For example, MSEH devices can be integrated into smart textiles, where nanostructured hygroscopic layers embedded in clothing harvest moisture and generate electricity to power low-energy sensors or health-monitoring wearables, eliminating the need for external batteries. Although designing and applying the new technology may take some time, this opens possibilities for energy-autonomous wearables in remote or off-grid settings. Moreover, with MSEH and TEPG’s recent successes to power small electronics in laboratory settings, scientists increasingly blur the boundaries between the nanogenerators’ subcategories, experimenting hybrid systems to maximize the system’s energy efficiency. For example, MXene, initially studied in TEPG for its conductive and hydrophilic properties, are now being explored in pizoelectric systems for its high mechanical flexibility and strength as flexible 2D structures, ideal for flexible sensors and energy harvesters, surface functionalization, as the functional groups, such as hydroxl, fluoride, and oxide, alter symmetrical structures to induce piezoelectricity, and high conductivity (Bae et al., 2022). This cross-disciplinary integration reinforces the high potential in the advances of currently less-spotlighted subcategories of nanogenerators.

IV. TEPG Key Sorbents and Performance Comparison

This section introduces key sorbents in the most cited literature within the TEPG community in the last decade and compares its specific performance, analyzing which composite materials recorded the highest efficiency.

One of most notable cellulose-based TEPG research, Yun et al. (2019), introduced a thin planar form cotton fabric (90 x 30 x 0.12 mm) coated with carbon black as the capillary medium. This carbon black coating provides a conductive pathway to channel the charge, also known as the “psuedostreaming” current. A single 90 x 30 mm panel produced an open-circuit voltage of 0.53V and short-circuit current 3.91 uA, leading to 2.1 uA power generation. The energy output per volume was reported as 1.14mWh/cm^3, indicating a specific energy capacity of 4.1 J per cm^3. This implies that a 2.2V LED light requiring ~20 mA could be lighted with several TEPG panels in series/parallel circuits, highlighting its vast potential as a passive energy generation source. The application of carbon black, a conductive and high-surface-area material, while the hydrophilic cotton provided continuous flow, resulting in modest energy generation at a low cost.

Moreover, a study by Bae et al. (2020) further enhances the set up in Yun et al., applying calcium chloride (CaCl2) on same carbon-coated cotton fabric, to create a closed-loop water cycle that mimics transpiration. After a few drops of water are initially added to begin the capillary flow, as water evaporates, the CaCl2 absorbs the vapor and releases it to re-wet the fabric. The device remained in similar dimensions to Yun et al. (2019) but with an additional layer of hygroscopic CaCl2. This research’s most significant achievement lies on prolonged period of TEPG operation, as what would normally have continued for merely an hour continued energy generation for several days. Results indicated that the implementation of CaCl2 enhanced the output, as the voltage rose to 0.74 V and current to 22.5 uA from approximately 0.5 V and 4uAwithout. This increased the power generation to 16-17uW, extending its period to light an LED from an hour or two to a week.

Another innovative study has been conducted by Lv et al. (2020), as the research presents a simple, low-cost generator using commercial air-laid paper with conductive carbon ink. Here, the paper acts as the sorbent, providing porous network for water transport, while the carbon ink forms a conductive film/electrode on the paper, simulating transpiration with commercially available products. Having one end of the paper strip slightly dipped in lithium chloride (LiCl) solution and the other end exposed, a continuous capillary flow has been formed to generate electricity. The strip is very thin and flexible (6 cm x 1 cm), and a single trip produced a continuous open-circuit voltage of 0.35 V and 33.9 uA under ambient conditions, corresponding to a raw 10^-5 W power generation. However, when dipped in de-ionized water, the performance recorded 0.17 V and 7.2uA. This further indicates that higher electrolytic solutions leads to better performance, due to enhanced electrical conductivity. The simple set up provided great stability, as the system had a consistent output over 120 hours, powering small electronics, including an LED, a pocket calculator, a digital watch, directly from TEPG. Despite cheap materials, the research widened the scope of materials implemented in TEPG, nearing power generation in advanced lab settings.

At last, other than natural cellulose-based fabric, Kaur et al. (2021) employs a porous ceramic (α-alumina) block as the water transport medium. The alumina had ~35% porosity with 50-200 interconnected pores. Without any additional conductive coating, the bare ceramic generates electricity once wet, due to its surface charge—alumina pores carry a negative charge in water. In this study, a 3.0 × 3.0 × 0.3 cm^3 rigid alumnia block was used, substantially thicker than the fabrics used in other studies. To simulate plant transpiration process, one end of the block is placed in water (~1.5 cm deep), while the other end is exposed to air, establishing a capillary-driven water transport pathway that enables continuous upward water flow and evaporation. As the alumina block was a rigid ceramic, it demonstrated lack of flexibility. However, the device was durable enough to function over a year in ambient conditions, compensating for the inflexibility. The system recorded an open-circuit voltage up to ~0.27 V stable output in standard ambient conditions, while it recorded a low short-circuit current ~1.2uA. The maximum instantaneous power was calculated as only 0.324 uW, but this output could be sustained over months with stable set up. Overall, the microporous alumina proved effective due to Alumina’s surface chemistry: Alumina’s negative OH- creates a strong EDL, and as water moves H+ cations drag, accumulating charge. The alumina ceramic demonstrated clear trade-offs: while it remained stable over a long period, avoiding issues of material delaminatoin that carbon coatings faced, it also recorded a particularly low short circuit current, as the conduction is only via ionic streaming, not electronic, leading to high internal resistance.

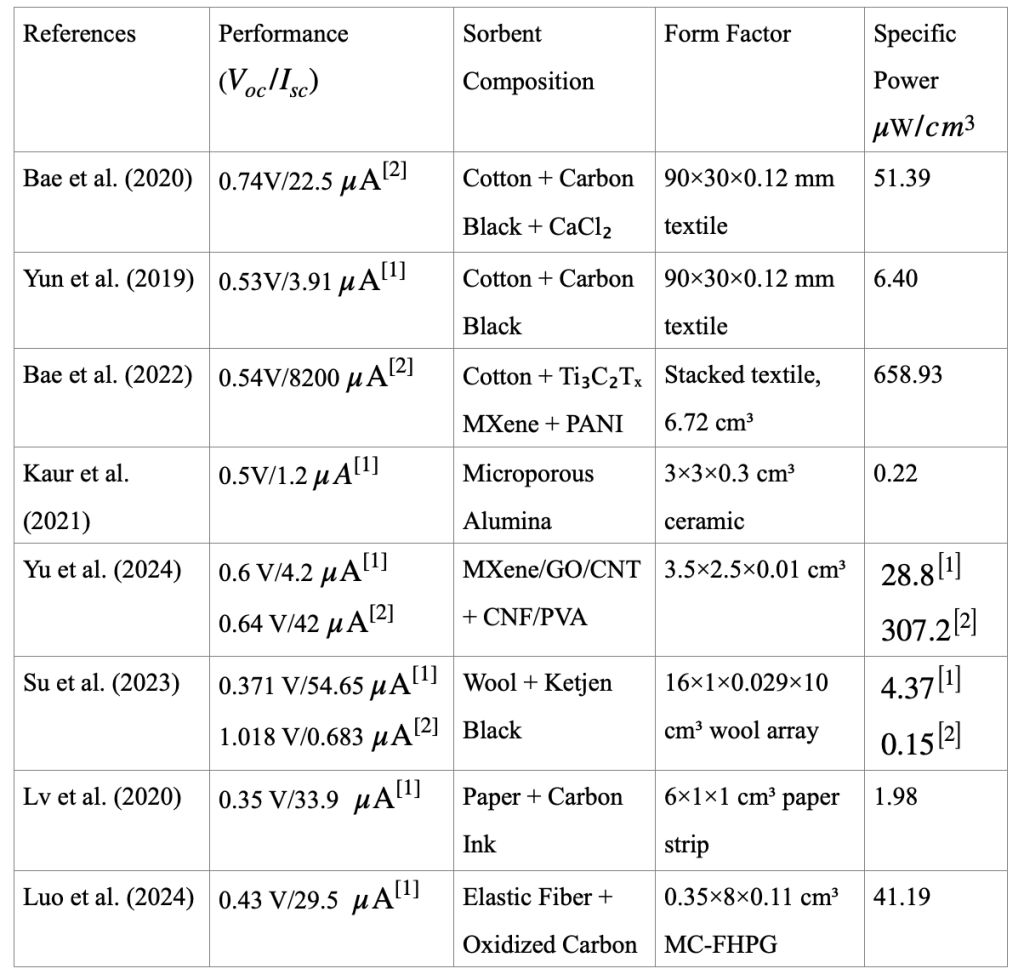

Table 2. Performance Comparison of TEPG Studies Published in Recent Literature. Specific power (mW/cm³) was calculated based on maximum power using Voc and Isc. Exponent [1] indicates testing in deionized (DI) water, while [2] indicates testing in ionized water.

Table 2 demonstrates the 8 most highly-impacted publications on TEPG, including information on each research’s performance (open-circuit voltage & short-circuit current), sorbent composition, form factor, and specific power. The table reveals natural cellulose-based sorbent to be the predominant sorbent model in TEPG, often enhanced with advanced materials that exhibit high hygroscopicity. In fact, the most highly cited and best-performing articles—Bae et al. (2020), Yun et al. (2019), Bae et al. (2022)—all used cotton combined with another material as their sorbent, highlighting the potential of enhanced cotton in TEPG. Additionally, the exponent numbers in the performance section indicate whether the experiment was conducted in deionized water [1] or ionized water [2], for more accurate comparisons.

The specific power was calculated through the following two equations with available open-circuit voltage and short-circuit current data. The calculated specific power is the maximum specific power that could be achieved in each experimental setting.

Some researches, including Yu et al. (2024) and Su et al. (2023), investigated performances under both deionized water and ionized water environments. As shown in Table 2, both studies yielded better performance in ionized (salt) water. Moreover, although Bae et al. (2020) replicates the experimental settings in Yun et al. (2019), it yielded greater specific power, as Bae et al. (2020) conducts the experiment in ionized water while Yun et al. (2019) in deionized water. When TEPG is conducted in ionized water environments, the presence of ions enhances charge carrier density and electrokinetic flow, increasing both voltage and current outputs. Though, values from deionized (pure) water hold greater significance, as most situations where TEPG and MSEH will be applied comprise ambient moisture or deionized water. However, in Bae et al. (2020), it was noted that without CaCl2 or other salts, the device stopped working within ~1 hour due to lack of moisture retention and ion supply. This still implies that there is a long journey that awaits before TEPG is applied commercially.

In conclusion, the comparative analysis of recent TEPG studies highlights the significant impact of sorbent composition, form factor, and water environments on device performance. Cotton-based systems, particularly those enhanced with conductive additives like Mxene and polyaniline (Bae et al., 2022), exhibit the highest specific power outputs—reaching up to 658.93 uW/cm^3. In contrast, ceramic and simpler textile setups, such as those using microporous alumina or uncoated cotton, display notably lower performance. Although it current performance do not yield enough to power daily electronics, considering its continuously rising performance over the past years and its ‘supernova’ status suggest a promising future.

V. Conclusion

By examining the current research trends in moisture-sorption-based and transpiration-driven electrokinetic energy harvesting, it is evident that they hold significant potential as rapidly growing subfields within nanogenerator research. Both the number of publications and the performance of reported devices have shown a steep upward trajectory in recent years. Although current outputs in TEPG remain in the microampere range—insufficient for commercial electronics—continued progress highlights its potential viability, especially when the system reaches the milliampere range. Moreover, as hybrid technologies, where MSEH and TEPG systems complement more promising energy generation technologies, develop, they will play a vital role in decentralized, location-optimized power solutions for sensors, wearables, and other low-energy devices.

IV. Acknowledgement

I would like to thank Professor Dichiara for his guidance throughout this study. His consistent support and insights have been pivotal to completing this research.

REFERENCES

Xu, J., Wang, P., Bai, Z., Cheng, H., Wang, R., Qu, L., & Li, T. (2024). Sustainable moisture energy. Nature Reviews Materials. https://doi.org/10.1038/s41578-023-00643-0

Bae, J., Tae Gwang Yun, Bong Lim Suh, Kim, J., & Kim, I.-D. (2020). Self-operating transpiration-driven electrokinetic power generator with an artificial hydrological cycle. Energy & Environmental Science, 13(2), 527–534. https://doi.org/10.1039/c9ee02616a

Yun, T. G., Bae, J., Rothschild, A., & Kim, I.-D. (2019). Transpiration Driven Electrokinetic Power Generator. ACS Nano, 13(11), 12703–12709. https://doi.org/10.1021/acsnano.9b04375

Bae, J., Soo Kim, M., Oh, T., Lim Suh, B., Gwang Yun, T., Lee, S., Hur, K., Gogotsi, Y., Min Koo, C., & Kim, I.-D. (2022). Towards Watt-scale hydroelectric energy harvesting by Ti 3 C 2 T x -based transpiration-driven electrokinetic power generators. Energy & Environmental Science, 15(1), 123–135. https://doi.org/10.1039/D1EE00859E

Kaur, M., Ishii, S., Nozaki, R., & Nagao, T. (2021). Hydropower generation by transpiration from microporous alumina. Scientific Reports, 11(1), 10954. https://doi.org/10.1038/s41598-021-90374-5

Yu, Z., Mao, J., Li, Q., Hu, Y., Tan, Z., Xue, F., Zhang, Y., Zhu, H., Wang, C., & He, H. (2024). A Transpiration-Driven Electrokinetic Power Generator with a Salt Pathway for Extended Service Life in Saltwater. Langmuir, 40(10), 5183–5194. https://doi.org/10.1021/acs.langmuir.3c03390

Su, H., Azadeh Nilghaz, Liu, D., Dai, L., Tang, B., Wang, Z., Razal, J. M., Tian, J., & Li, J. (2023). Self-operating seawater-driven electricity nanogenerator for continuous energy generation and storage. Chemical Engineering Journal Advances, 14, 100498–100498. https://doi.org/10.1016/j.ceja.2023.100498

Lv, Y., Gong, F., Li, H., Zhou, Q., Wu, X., Wang, W., & Xiao, R. (2020). A flexible electrokinetic power generator derived from paper and ink for wearable electronics. Applied Energy, 279, 115764. https://doi.org/10.1016/j.apenergy.2020.115764

Luo, G., Xie, J., Liu, J., Luo, Y., Li, M., Li, Z., Yang, P., Zhao, L., Wang, K., Maeda, R., & Jiang, Z. (2023). Highly Stretchable, Knittable, Wearable Fiberform Hydrovoltaic Generators Driven by Water Transpiration for Portable Self‐Power Supply and Self‐Powered Strain Sensor. Small, 20(12). https://doi.org/10.1002/smll.202306318

Triboelectric Nanogenerator (TENG) Market Size, Forecasts 2033. (2023). Spherical Insights. https://www.sphericalinsights.com/reports/triboelectric-nanogenerator-teng-market

Nanogenerator Market Size, Share & Growth By 2033. (2025). Marketgrowthreports.com. https://www.marketgrowthreports.com/market-reports/nanogenerator-market-113380

Research,https://virtuemarketresearch.com, V. M. (n.d.). Nanogenerator Market | Size, Share, Growth | 2023 – 2030. Virtue Market Research. https://virtuemarketresearch.com/report/nanogenerator-market

Verified Market Reports. (2025, February 17). Nanogenerator Market in United States 2025 | Size, Share and Future Outlook. Verified Market Reports. https://www.verifiedmarketreports.com/product/nanogenerator-market/

Number of power outages by key U.S. state 2017. (n.d.). Statista. https://www.statista.com/statistics/1078354/electricity-blackouts-by-state/

About the author

Jinwook (James) Chang

Jinwook is an aspiring environmental innovator bridging environmental science, energy, and policy to drive sustainable solutions from the lab to the real world. Part scientist, part historian, James draws on lessons from the past to shape innovations that power a cleaner tomorrow. (Website: https://www.jamestechgarage.com/)