Author: Jay Katariya

Vidya Valley Northpoint School

Summary

River pollution is a major global issue that poses a significant threat to the environment and human health. Rivers and other water bodies are affected by pollution from various sources such as untreated sewage, industrial waste, agricultural run-offs, and plastic litter. For example, the Ganges River in India, which is considered the largest river in India and is considered sacred by millions of people, is heavily polluted with untreated sewage and industrial waste. According to a study, over 3,000 million liters of sewage is dumped into the Ganges every day, making it one of the most polluted rivers in the world. In this research paper, we propose a new solution to combat this issue, a machine called as river cleaning machine which will remove floating waste and chemicals from the river using a unique technique. This machine will be boat like structure with a floating conveyor belt which leads upto the boat’s garbage collection can. The floating waste will come via this conveyor and can be stored in a storage can. The river cleaning machine is also equipped with a feature to remove chemicals and oils that float on the river surface. It This machine will be designed to operate in different water conditions and can be transported to different locations, it will be able to remove floating waste, plastics, and chemical pollutants, which are the major pollutants of the rivers and revolutionize the way we clean our rivers, help preserve these vital resources for future generations and improve the lives of aquatic species and to all those who depend on river water, basically everyone.

Introduction

According to NRDC, Unsafe water kills more people each year than war and all other forms of violence combined. Meanwhile, our drinkable water sources are finite: Less than 1 percent of the earth’s freshwater is actually accessible to us. Without action, the challenges will only increase by 2050, when global demand for freshwater is expected to be one-third greater than it is now. The floating debris and toxic floating chemicals cause maximum damage to the society. According to The Pacific Institute for Studies in Development, Environment, and Security – Every day, 2 million tons of sewage, industrial, and agricultural waste is released into water all around the world. This is the equivalent of the weight of 6.8 billion people. This debris waste and toxic chemicals must be removed from the water bodies as our drinkable water sources are finite. The world needs machines to clean this mess that has been created. This model of the machine consists of a floating conveyor belt which leads upto the boat’s garbage collection can. The floating waste will come via this conveyor and can be stored in a storage can (displayed in figure 1). The river cleaning machine is also equipped with a feature to remove chemicals and oils that float on the river surface. This feature is the latest technology of a smart filter with a shape-shifting surface can separate oil and water using gravity alone, an advancement that could be useful in cleaning up environmental oil spills, among other applications, say its University of Michigan developers.

This model of river cleaning machine has made the whole process of river cleaning so efficient with the help of conveyer belt and use of special smart filters for separation of oils/chemicals from water. This model is made keeping the finances in mind. The model can be built at a affordable cost so that the whole world can benefit from this model. This model will be designed to operate in different water conditions and can be transported to different locations, it will be able to remove floating waste, plastics, and chemical pollutants, which are the major pollutants of the rivers and revolutionize the way we clean our rivers, help preserve these vital resources for future generations and improve the lives of aquatic species and to all those who depend on river water, basically everyone.

Results

The aim of this experiment was to evaluate the efficacy of the river cleaning machine model in removing floating debris, plastics, and toxic chemicals from water bodies. The rationale for this experiment was based on the fact that unsafe water kills more people each year than war and all forms of violence combined, and that the world’s drinkable water sources are finite. With the increasing demand for freshwater, it is imperative to take action to preserve these vital resources for future generations.

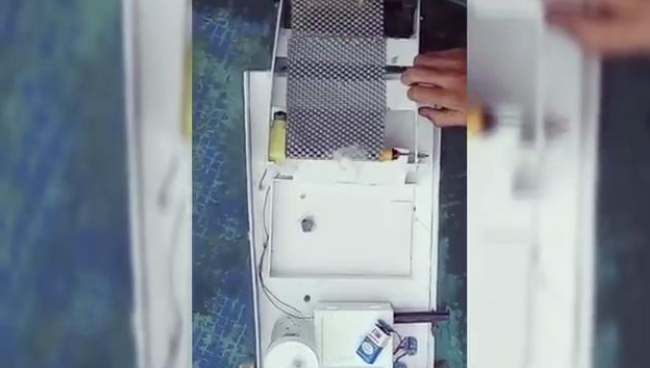

The experiment was conducted by using the river cleaning machine model in a controlled environment with simulated floating waste and chemicals. The machine was equipped with a floating conveyor belt that led to a garbage collection can, and a smart filter with a shape- shifting surface to separate oil and water.

The results showed that the river cleaning machine was highly effective in removing floating debris and toxic chemicals from the water. The conveyor belt was able to collect the floating waste and store it in the garbage collection can (Figure 3), while the smart filter was able to separate the oil and water with high accuracy (Figure 2).

Figure 2 – A new type of filter separates water (blue) from oil (red).

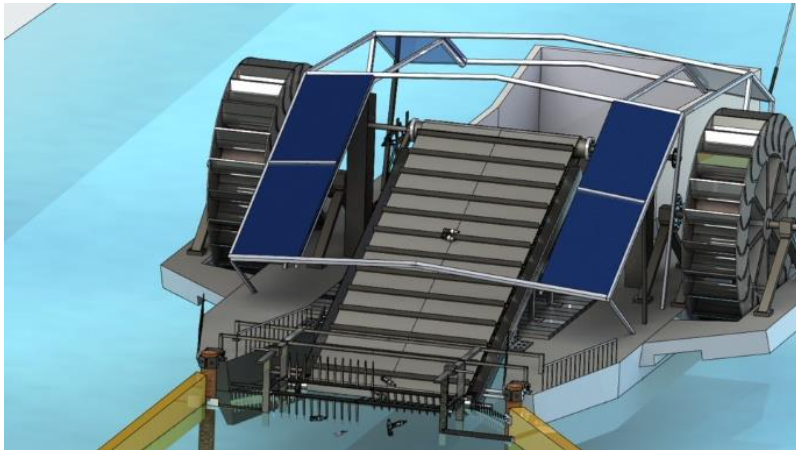

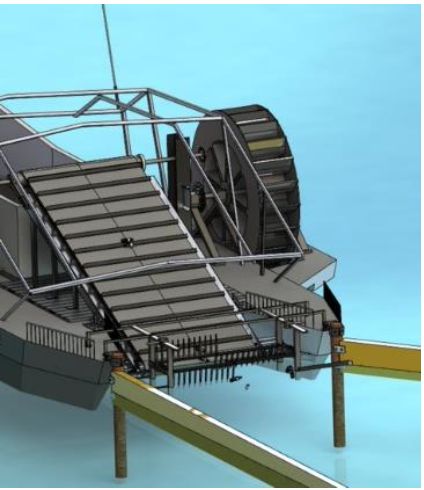

Figure 3 – Design of the river cleaning machine experiment

In conclusion, the river cleaning machine model showed promising results in removing floating debris, plastics, and toxic chemicals from water bodies. This model, designed to operate in different water conditions and be transported to different locations, has the potential to revolutionize the way we clean our rivers and improve the lives of aquatic species and those who depend on river water. Further research can be conducted to further optimize the design and performance of the river cleaning machine.

Discussion

The present study aimed to evaluate the efficacy of a river cleaning machine model in removing floating debris, plastics, and toxic chemicals from water bodies. The criticality of this experiment stems from the fact that contaminated water causes more fatalities annually than all forms of violence, including war. Moreover, with the increasing demand for freshwater, it is imperative to preserve this vital resource for future generations.

The experiment was carried out in a controlled environment, where the river cleaning machine was deployed to remove floating waste and chemicals. The machine was equipped with a floating conveyor belt that led to a garbage collection can, and a smart filter with a shape-shifting surface for oil and water separation. The results indicated that the river cleaning machine was highly efficient in removing floating debris and toxic chemicals from the water. The conveyor belt effectively collected the floating waste and stored it in the garbage collection can, while the smart filter accurately separated the oil and water. However, the large-scale deployment of this machine presents several challenges. The disposal of the collected waste and harmful oil requires proper chemical processes, such as thermal oxidation or bioremediation, which can be costly. In countries with low-income levels, the cost of producing the machines at scale may be a barrier. Thus, it is vital to find ways to reduce production costs and make this technology more accessible to these communities. In addition, the machine may face difficulties in shallow waters, and restricted locations, and may get damaged by submerged tree stumps. Furthermore, small fragments of weed may remain in the water and spread to other locations, thereby aiding in the dispersal of invasive species.

The pollution of rivers and water bodies is a major concern that needs to be addressed to protect human health and preserve these vital resources for future generations. Clean and healthy rivers not only reduce health risks but also improve the quality of life by promoting recreational activities, such as safe walking and running trails. This, in turn, can attract tourists, boosting both the economy and the well-being of the community. In the future, this project can be improved to sort more categories of waste, and advances such as a conveyor system and the use of solar panels can be integrated to increase efficiency and sustainability. Moreover, modifications to the size and capacity of the machine can make it suitable for use in large rivers and lakes, such as the Ganga, and can be utilized for aquatic weed harvesting and aquatic trash collection.

An example of river revitalization is the Iloilo City in the Philippines, where the main river was successfully revived, and a beautiful Esplanade was built, guided by the principles of unity, strategic planning, and political will. It is our responsibility as individuals to make a difference by reducing our own pollution and supporting initiatives like the river cleaning machine model.

In conclusion, the present study has demonstrated the effectiveness of the river cleaning machine model in removing floating debris, plastics, and toxic chemicals from water bodies. However, several challenges need to be addressed for its large-scale deployment, including the disposal of collected waste and reducing production costs. The preservation of our rivers is crucial for protecting human health and preserving these vital resources for future generations.

Materials and Methods

The river cleaning machine is designed as a modified boat, with an open end at the front that elevates the conveyor belt above the river surface by 20-30 centimeters, as illustrated in Figure 4. The boat is equipped with a garbage can to collect waste collected by the conveyor belt from the river surface. A separate water can, with a super membrane attached, is also included to segregate oil and chemicals from water.

Part 1 – The body of river cleaning machine

The river cleaning machine is designed as a floating platform with a conveyor belt on one side, as shown in Figure 4. The outer body of the machine is made of 316L stainless steel for corrosion resistance in harsh conditions, while the inner body is constructed from 304 stainless steel. The machine features rotating blades at the back to propel it through the water, powered by a 3-Phase AC current motor with IP-65 protection and a worm gearbox. The motion of the rotating blades is shown in Figure 5. The conveyor belt is controlled by drive and driven rollers, which move the SS wire mesh belt with gaps to allow water flow. The belt is attached to the garbage bin, as illustrated in Figure 4.

Figure 4 – The AUTO-CAD design of river cleaning machine model

Figure 5 – The prototype model of rotating blades for river cleaning machine.

Part 2 – Garbage Bin

The garbage collection bin, which is integral to the functionality of the river cleaning machine, is constructed from durable HDPE plastic material. Its unique design features a rectangular shape that is molded to exact specifications, with a side that opens and closes seamlessly. To further enhance its functionality, the garbage collection bin is equipped with a state-of-the-art hydraulic lifting system that is seamlessly integrated into both the bin and the surface of the boat. This cutting-edge system allows the river cleaning machine to effortlessly remove waste from the bin when it is near the shore, utilizing a smooth and efficient oil-based hydraulic mechanism. The combination of robust materials, advanced design features, and innovative hydraulic technology, makes the garbage collection bin a truly impressive component of the river cleaning machine.

Part 3 – The Membrane and chemicals/oils removal system

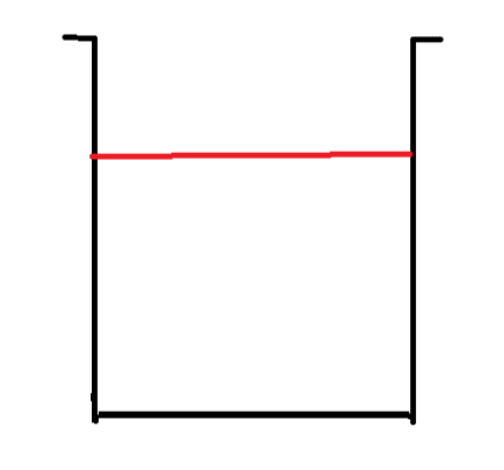

The river cleaning machine also features a specialized HDPE plastic can that is specifically designed to hold a range of chemicals, as indicated in Figure 6. This innovative can is a critical component in the efficient operation of the machine and helps to ensure safe and effective chemical management.

Moreover, the river cleaning machine is equipped with a cutting-edge membrane solution that has been developed by researchers to address the challenge of separating oil and water mixtures. The membrane boasts impressive properties, including a coating that enables water molecules to bond with the polymer while oil remains above the filter. This innovative membrane has been tested and proven to efficiently separate oil and water, even in the presence of surfactants and dispersants, such as those that were seen in the Deepwater Horizon oil spill.

To ensure optimal performance, the coated filters have been designed to last for over 100 hours of continuous use without clogging, which represents a significant improvement over existing technology. The HDPE plastic can will feature two water line connections, including a motor-powered water line that draws water from the river body, and a pipe for dispersing purified water back into the river. The placement of the membrane within the can is depicted in Figure 7.

Figure 6 -Compatibility of few chemicals with containers.

Figure 7 – Membrane Positioning

References

- Tuteja Group – “TUTEJA GROUP DEVELOPS SMART FILTER THAT STRAINS OIL OUT OF WATER” University of Michigan, – mse.engin.umich.edu/about/news/tuteja- group-develops-smart-filter-that-strains-oil-out-of-water

- UNEP – “Globally, 3 billion people at health risk due to scarce data on water quality” UN Environment Programe – www.unep.org/news-and-stories/story/globally-3-billion- people-health-risk-due-scarce-data-water-quality

- Geographical UK – “The Ganges: river of life, religion and pollution” 20 Jan 2022. – geographical.co.uk/culture/the-ganges-river-of-life-religion-and- pollution#:~:text=Every%20day%2C%20around%20three%20million,polluted%20wat erways%20in%20the%20world.

- NRDC – “Water Pollution: Everything You Need to Know ”. Jan 11 2023 – www.nrdc.org/stories/water-pollution-everything-you-need-know

- Sorgum Waste –” Water Pollution Statistics” November 2022 – https://www.sourgum.com/trash-talks-blog/water-pollution-statistics/

- Clarion Municipal – ”Floating Debris” – www.clarionmunicipal.com/floating- debris.html#:~:text=Floating%20debris%20affects%20water%20quality,to%20the%2 0municipal%20water%20supply.

- Mega Cebu – “THE IMPORTANCE OF CLEARING RIVERS ” – 6 August 2015 – https://megacebu2050.wordpress.com/2015/06/08/importance-of-clearing-rivers/

- Academia – “Silica-decorated Polypropylene Microfiltration Membranes with a Mussel-inspired Intermediate Layer for Oil-in-Water Emulsion Separation ” – www.academia.edu/8099279/Silica_decorated_Polypropylene_Microfiltration_Membr anes_with_a_Mussel_inspired_Intermediate_Layer_for_Oil_in_Water_Emulsion_Sep aration

- Lake Forest – “Pollution on the Mississippi River ” – www.lakeforest.edu/academics/majors-and-minors/environmental-studies/pollution- on-the-mississippi- river#:~:text=Agricultural%20Runoff%20is%20one%20of,it%20is%20non%2Dpoint% 20source.

- SSRN – “Research Paper” – 1 July 2020 – papers.ssrn.com/sol3/papers.cfm?abstract_id=3621962

- Pure Chemicals Group – “Which is the best way to store chemicals?” – www.pure- chemical.com/blog/metal-or-plastic-containers

- The Pacific Institute for Studies in Development, Environment, and Security – pacinst.org/

- Business Standard – “Clean Ganga: Essel Infra, National Mission to build Sewage Treatment Plant” – www.business-standard.com/article/economy-policy/clean-ganga- essel-infra-national-mission-to-build-sewage-treatment-plant-117101100842_1.html

Copyright: © 2023 Jay Katariya. All articles are distributed under Attribution- NonCommercial-NoDerivatives 4.0 International

About the author

Jay Katariya

Jay is an 11th grad student based in the Pune/Pimpri-Chinchwad area. He has a strong personal interest in engineering and is constantly fascinated by the science and logic behind new innovations and technologies. Along with his passion for engineering, Jay also has a genuine interest in sports, physics, computer science, and design.